- Motor/transmission marriage

- Motor installation

- Front suspension finalized

- Battery boxes fabricated

- Color plan established

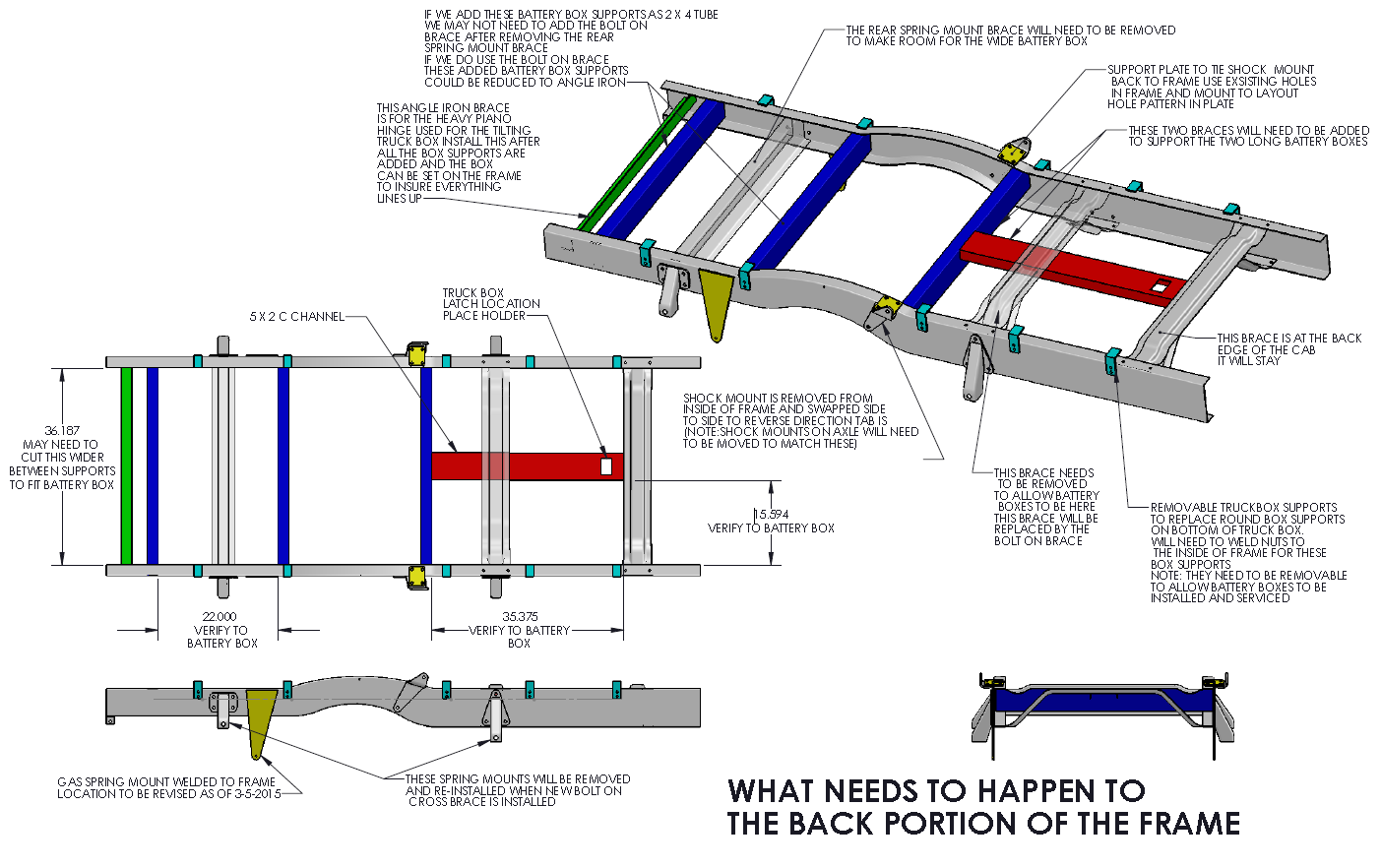

- Frame cross member removed

After Duane and Peter coated the adapter plate with Alodine to prevent corrosion, the motor could finally be married to the transmission.

To the upper right you can see (from bottom to top) the motor, adapter plate, and the flywheel/clutch assembly. The tricky part was to make sure that the motor shaft and transmission shafts are close to touching, but not quite.

Turns out that Jon had it figured right! Perfecto.

Jon & John wrestled it all together. Here it is, ready for installation.

Ben and David wrapped up the lowering of the front end. It was an amazing transformation when we set it on the ground. It looks tuff man! (that's 70's tuff).

Jason and Rob are coming to consensus on color. White with orange details (roof, transmission, graphics). Interior of the engine compartment, cab, and bed will be gray.

This next week should see the fitting of the battery boxes and welding in of new cross members. Rob and Jason are also committed to getting the gray painted.

I will also be ordering the final bits of HV stuff. Once the boxes are in, we can try running this baby!

|

| Jason & Rob discussing color |

|

| The Friday Stude Group discussing rear suspension |